-

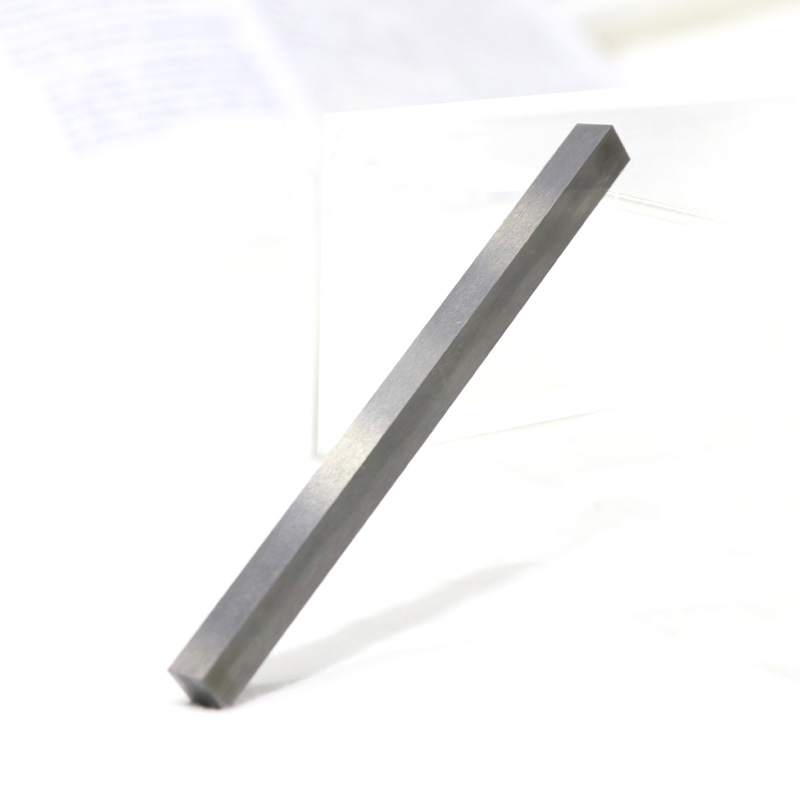

Tungnste square cork ho ea ho pampiri e 70 80% ea koae

MK8 MK9 PROS Mayr Mayr Machine Blade Blade Khalase e sebelisoang bakeng sa pampiri ea koae, e metsetsang likarolo ..

-

125 * 25,5 *

Ho sebetsa koae ho hloka lisebelisoa tse nepahetseng le tse lekaneng ho netefatsa hore sehlahisoa sa ho qetela se kopana le maemo a boleng bo batlang ho baloa ke bareki. 124 * 25.5 * 1.1

-

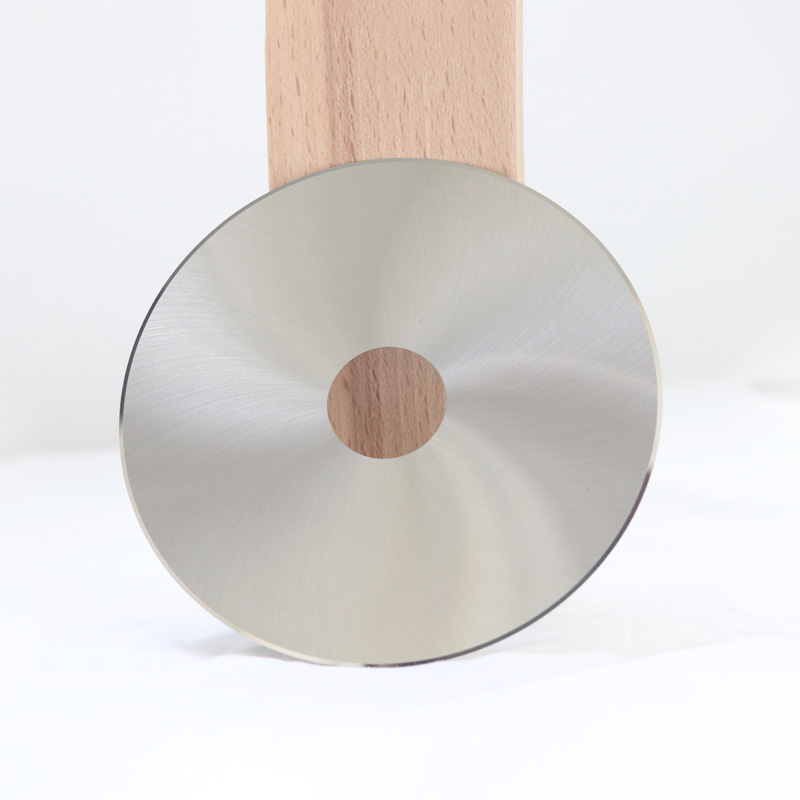

Hungsten carbide li-skimide tse potolohileng bakeng sa ho seha hoa koae ea koae

Linoko tsa rona tsa marang-rang tsa koae tsa koae li hlahisoa ka mokhoa o hlakileng le ho seha maraba

-

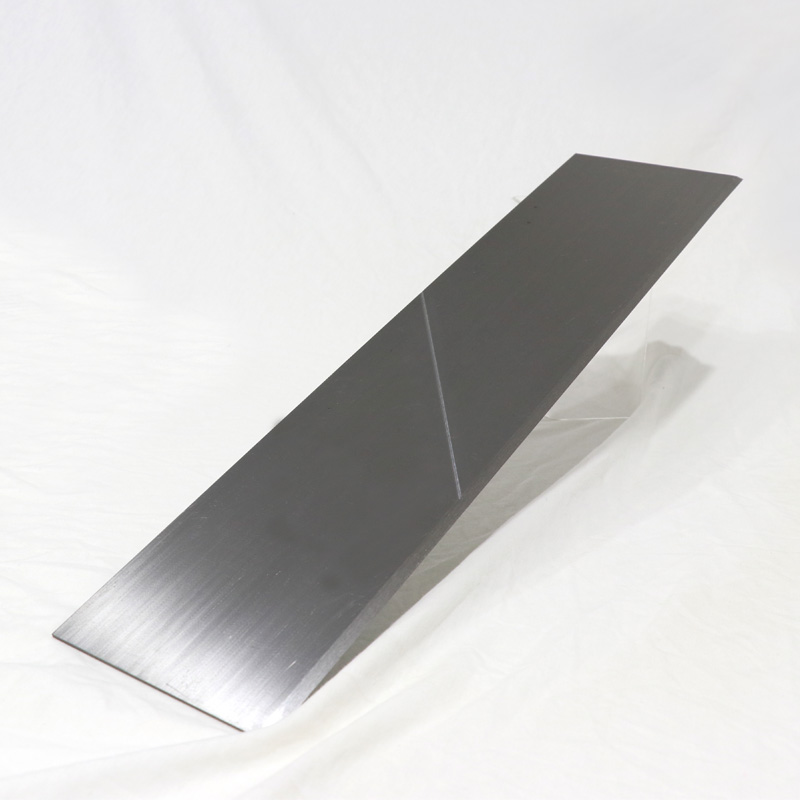

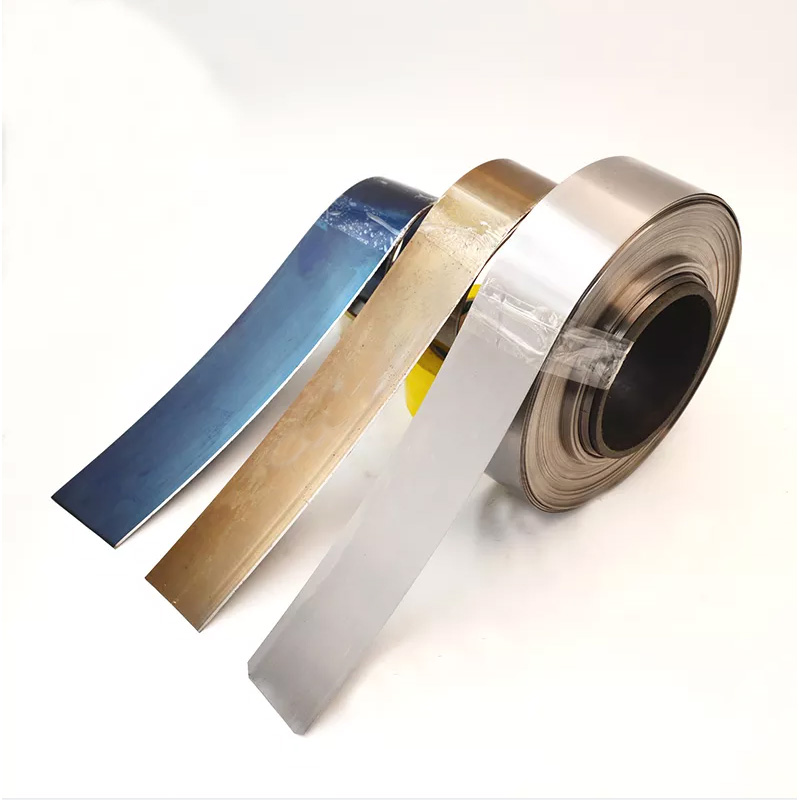

Kth KTC le KTF Long Blades bakeng sa makhasi a koae a koae

Ho roala malelele bakeng sa ho kuta makhasi ho loketse metjho e tsoang ho koae e ngata, 'me tse ling tsa 419x111111.5mmm100x1.5mm. Lithibelo li etsoa haholo ka har'a thepa ea carbide ea carbide, empa lisebelisoa tse ling li kenyeletsa M2 HS le D2 li fumaneha.

-

Mabili a daemane bakeng sa ho otla ha boima bo boholo bo sa foleng

E tsejoang e le e 'ngoe ea thepa e thata ka ho fetisisa lefatšeng, kemiso ea daemane e fana ka ts'ebetso e kholo ha e sebelisoa likoto tse sa sebetseng. Linofu tsa daero tsa takatso tsa takatso li entsoe ka nickel kapa ka koporo ea koporo e fanang ka bophelo ba mabili. Mabili a rona a bohale a phahamisang a tla ka sebopeho se sephara ho kenyeletsa le li-disc tsa sephara, li-cones, li-cylinders, li-cumlinders, li-coes le linoelo.

-

Flaing Cup Cup Diamond Grinding Grinding Wheels bakeng sa Tiles Camten Carbide Cutting

Meetso ena ea mofuta oa Resin Bond - Lebili le fetohang bakeng sa ho fetolela lisebelisoa, le li-skiling, ho makatsa lihlahla, ho fofa ha limela tsa ho sesa.

-

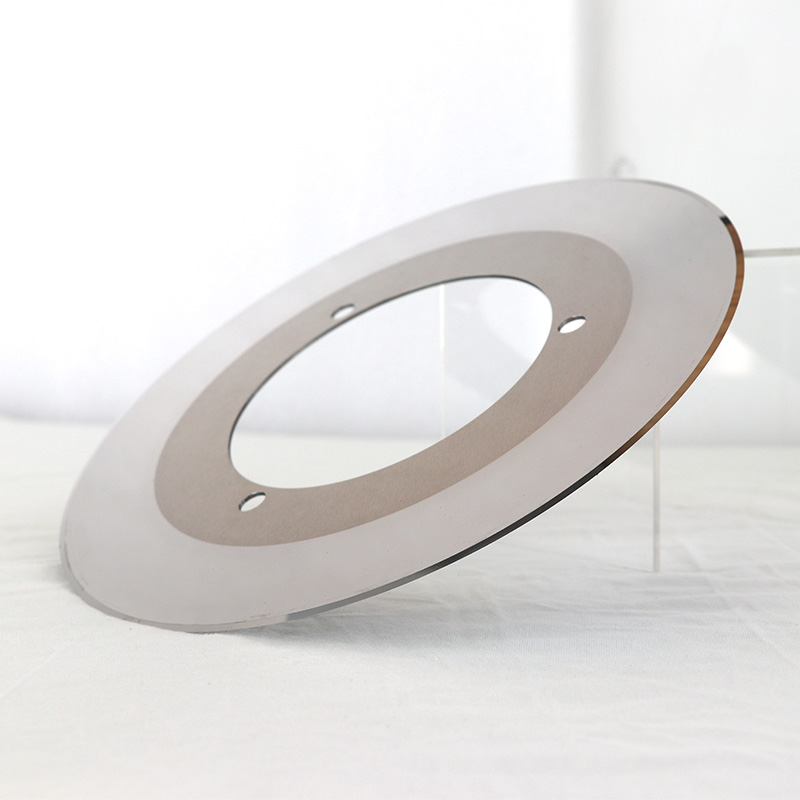

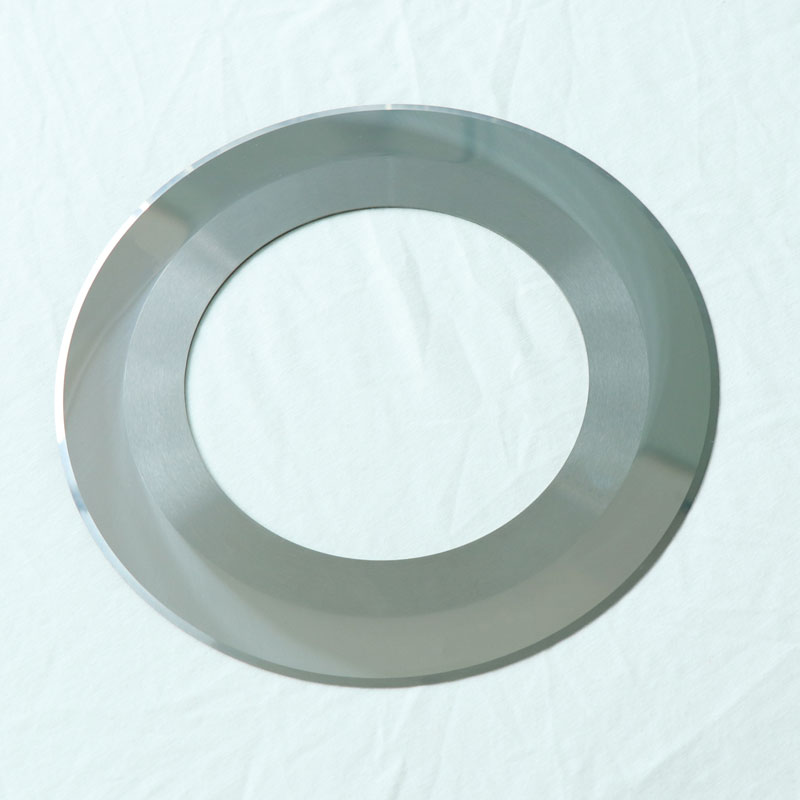

Li-agnati tsa agnati tungsten cirtern tc li-bluebbor cookie cookir

Agnati Blade e chitja φ240 * φ115 * 1 mm e sebelisoa bakeng sa ho seha pampiri e kolobisitsoeng. Knife ea slite e entsoe ka lisebelisoa tsa carbide tsa tungsten. Ho intšaphe, re sebelisa lisebelisoa tsa Carbide tse tiileng tsa 100%.

Re na le feme ea rona ea Blade e se nang letho, re etsa vacuum a silliloeng fekthering ea rona. Ka lebaka lena, re tiisa hore boleng bo tloha qalong.

Ha ho bapisoa le tšepe e tloaelehileng (tšepe e se nang mabele, HSS, carbon tšepe) Blades. Ho na le lehare la rona le lelelele le lelelele la ho sebetsa ho sebetsa, mocheso o phahameng o phahameng, ho ikarola ho feta, ho nepahala ho phahameng, ho thibela thata, ho thibeloa ke masene, a fokola haholo.

Re moetsi oa ho qetela mme lehare lena ke karolo ea rona e tloaelehileng. Re na le setoko sa ho se sebetse hantle. Kahoo o ka fumana bongata kamoo o ratang le ho fumana theko ea tlholisano le eona. Ka lebaka la rona ke moetsi, re ka fana ka tharollo e ntlafatsang haholoanyane ho moreki le ho fana ka litšebeletso tsa Oem le tšebeletso ea OMM le tšebeletso ea OMM.

-

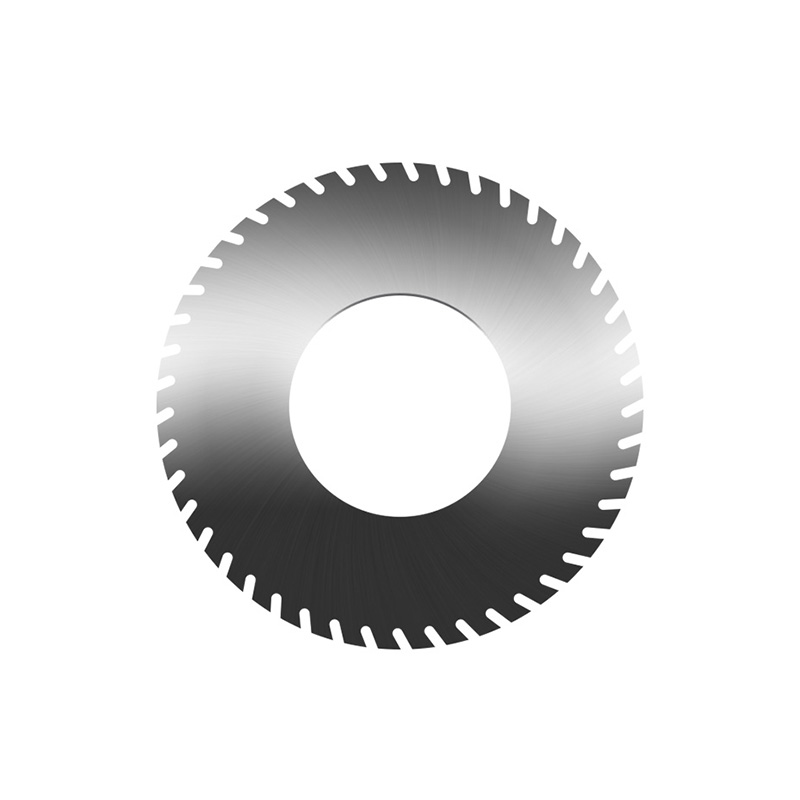

Tungns Carbide Selbor Slur Clictor Cortagated Cardboard Coolboard Free Colors

Slitfter Blade 200x12228X1.2mm e sebelisetsoa ho seoa pampiri e halikiloeng. Knife ea slite e entsoe ka lisebelisoa tsa carbide tsa tungsten. Ho intšaphe, re sebelisa lisebelisoa tsa Carbide tse tiileng tsa 100%.

Re na le feme ea rona ea Blade e se nang letho, re etsa vacuum a silliloeng fekthering ea rona. Ka lebaka lena, re tiisa hore boleng bo tloha qalong.

1. Ha e bapisoa le tšepe e tloaelehileng (tšepe e se nang mabele Ho na le lehare la rona le lelelele le lelelele la ho sebetsa ho sebetsa, mocheso o phahameng o phahameng, ho ikarola ho feta, ho nepahala ho phahameng, ho thibela thata, ho thibeloa ke masene, a fokola haholo.

2. Bophelo bo bolelele ba tšebeletso, ts'ebetso e phahameng ea litšenyehelo.

3. Phello e ntle ea ho khaola, ntlafatsa boleng ba pampiri, ha ho na sebaka se sehiloeng se sehiloeng, ha ho na likhahla tsa mosebetsi.

4. Ho nepahala ho phahameng le ho hanyetsa hamolemo ho hanyetsa.

5. Ts'ebetso e tšepahalang (mochini o fokolang oa mochini o tlase)

-

Hungsten carbide calting Genting bakeng sa libuka tsa book

Liphetoho tse khethehileng li fokotsa matla a hloekileng, fana ka sepheo se phahameng ka ho fetisisa le ho thibela litlamorao tse matla, esita le ka li-block tse boima le pampiri e thata. Lisebelisoa tsa tagion li otloloha litloaelo ebe u li-upolotiki tse sa tloaelehang.

-

Hungsten carbide Milling o ile a bona li-skives le lithipa tse futhumetseng bakeng sa indasteri ea khatiso ea ho hatisa

"Takatso ea" Tabi ea Carbi Re na le lilemo tse 15 tsa ho hlahisa carbide ea tungsten le meno 'me li na le botumo bo pharaletseng' marakeng. Ho na le thepa e telele haholo le ho thatafala haholo, setoko sa thepa e tloaelehileng. Re khetha ka hloko sehlopha se hlokahalang bakeng sa ts'ebetso e nepahetseng e thehiloeng lilemong tsa boiphihlelo tšimong.

-

Lehlakare la Surase ea Trimmer Knife bakeng sa indasteri ea khatiso

"Passion" -Kour ea lithipa-tsa liindasteri bakeng sa indasteri ea khatiso ea litaba ka poso. Re tlisetsa liqhakane le lisebelisoa tsa baetsi bohle ba mochini, joalo ka: Polar, Duhleberg, Senator ea Schneider le tse ling.

-

Ngaka e nyenyefatsa li-blades bakeng sa indasteri ea khatiso

Mechine ea khatiso ea matlafatsa e sebetsa ka ho kopanya anilox roller le ngaka e jang thepa ho etsa hore ngaka e be le eona. Ho latela kopo, Lamella, beljha, belj kapa li-blades tse otlolohileng ka metsamao e chitja e sebelisetsoa ho kopanya enke. Ka lebaka la bokaholimo ba Anilox Baroetsana ba laeseso, ngaka e nyane e khothaletsoa. Ka kakaretso, lehlakore le tšesaane la jarede le lumella ho opeloa ke ho hloekisa. Ho bohlokoa haholo bakeng sa Ngaka e hantle bakeng sa bophelo bo botle ke kamano lipakeng tsa li-celriguurtions (sebopeho / palo) ebe o jare botenya.