-

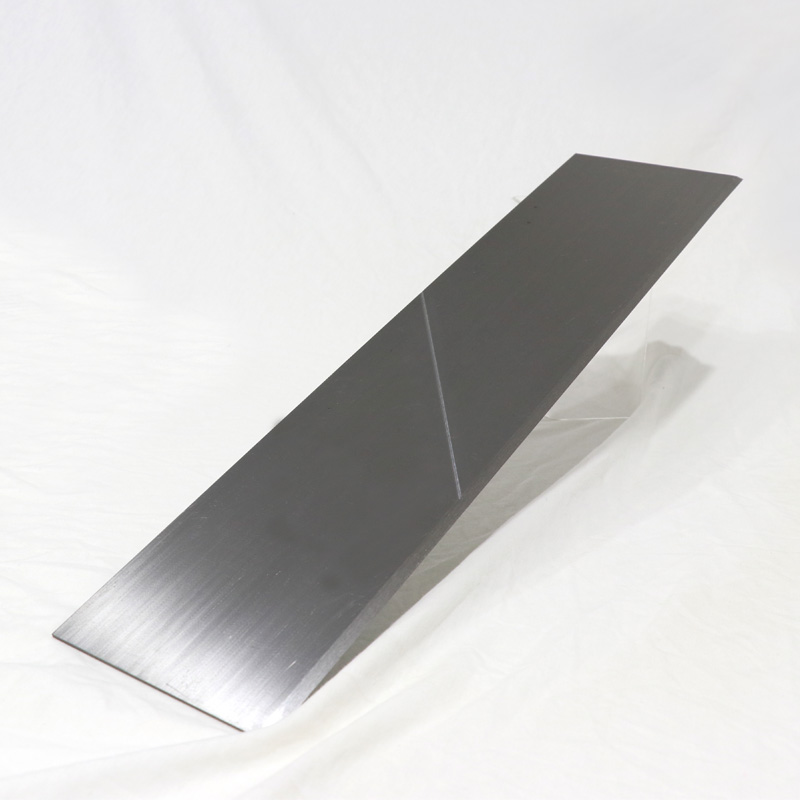

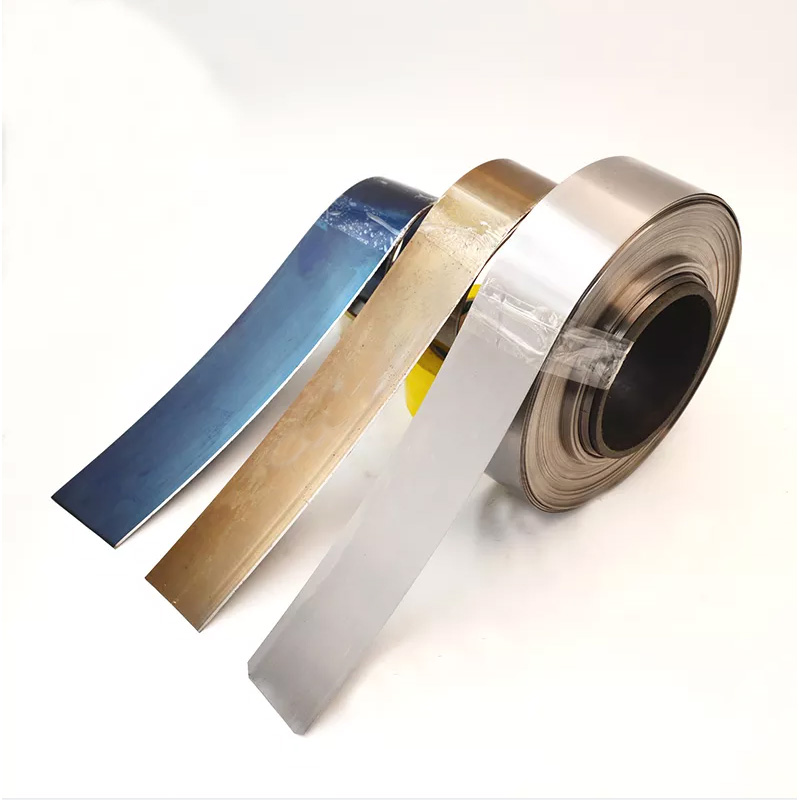

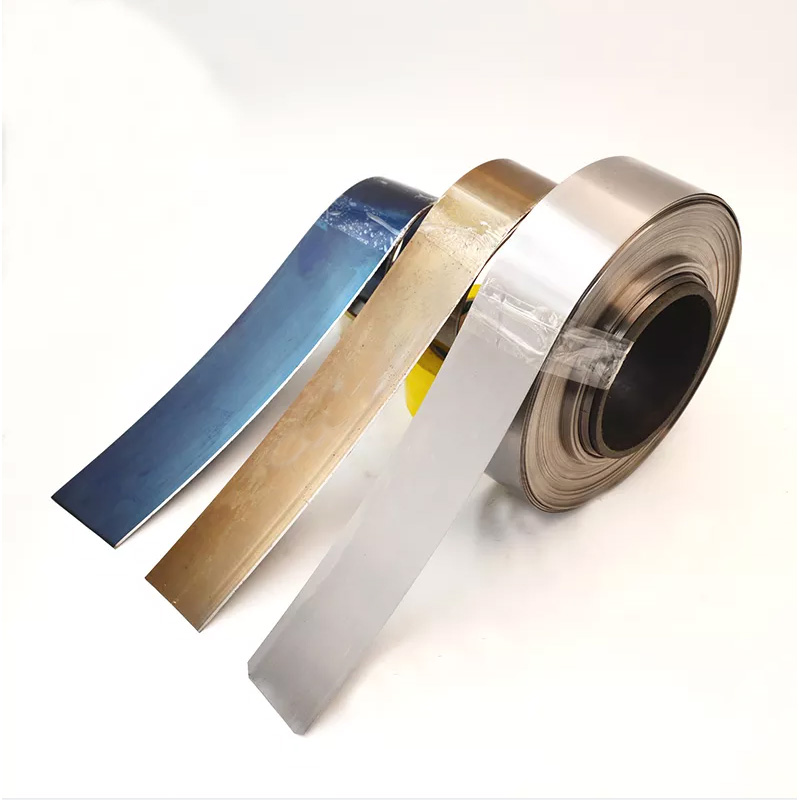

KTH KTC le KTF Long Blades bakeng sa koae Makhasi a Seha

Li-blades tse telele tsa koae bakeng sa ho seha makhasi li loketse mechini ea mantlha ea koae, joalo ka KTH, KTC le KTF, joalo-joalo. Re ntse re etsa li-cutter blades ka bongata, 'me tse ling tsa boholo bo tsebahalang li fumaneha ho tsoa stock, joalo ka 419x170x2. .0mm, 419x125x1.5mm le 419x100x1.5mm.Lithipa li entsoe haholo ka thepa ea tungsten carbide, empa lisebelisoa tse ling tse kenyelletsang M2 HSS le D2 lia fumaneha.

-

Mabili a Taemane Bakeng sa ho Hlōla Lintho tse sa Feleng tse thata tse phahameng

E tsejoa e le e 'ngoe ea lisebelisoa tse thata ka ho fetisisa lefatšeng, abrasive ea daemane ea maiketsetso e fana ka ts'ebetso e phahameng ha e sebelisoa likotong tsa mosebetsi tse se nang ferrous.Mabili a silang a taemane a PASSION a entsoe ka nickel kapa koporo e etsang hore mabili a phele halelele.Mabili a rona a maholohali a abrasive a tla ka libopeho tse ngata ho kenyeletsoa li-discs tse bataletseng, li-cones, li-cylinders, li-cones le likopi.

-

Mabili a sila a kopi ea daemane bakeng sa tungsten carbide cutting Blades

Mofuta ona oa lebili le silang la resin bond e sebelisoa bakeng sa lisebelisoa tse fetolang carbide, lisebelisoa tsa ho sila, li-milling cutters, reamers, broaches, sila carbide le tšepe e thata, lithipa tsa alloys, mahare a sakha, ts'ebetso ea ho sila ea serrated le ho sila sefahleho sa ho qetela.

-

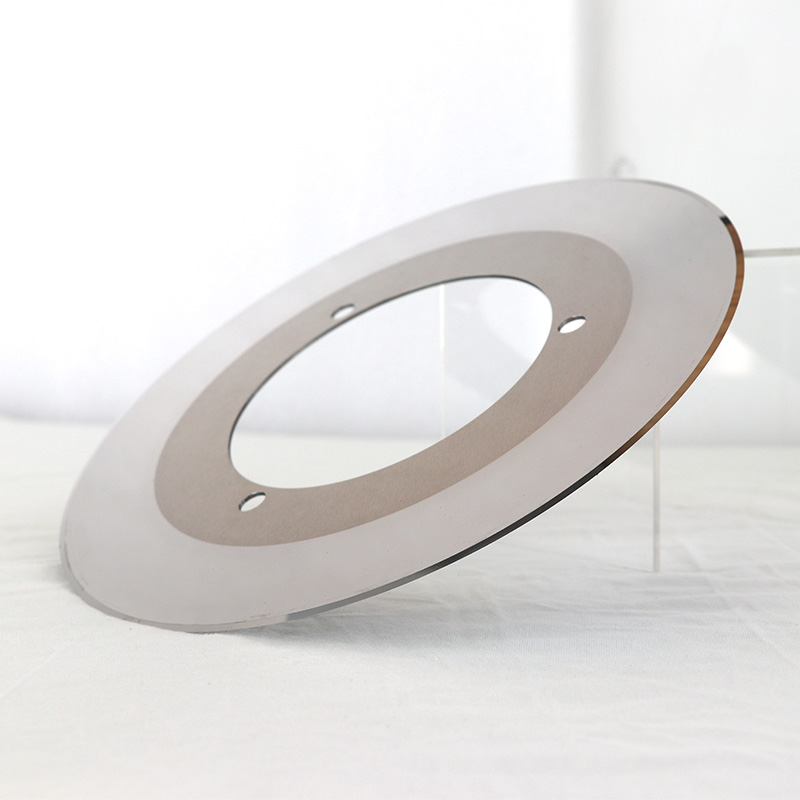

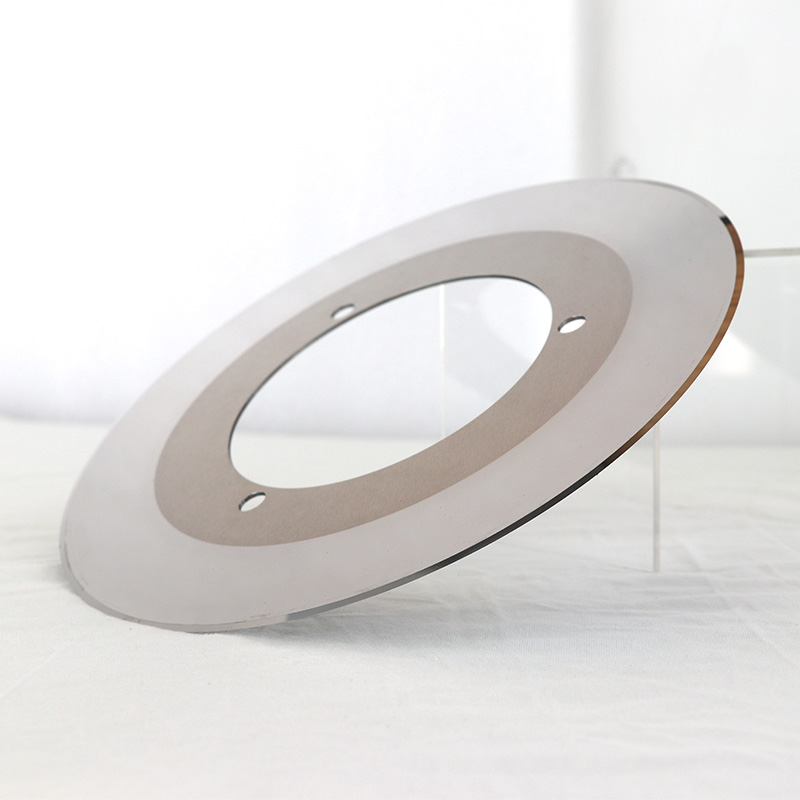

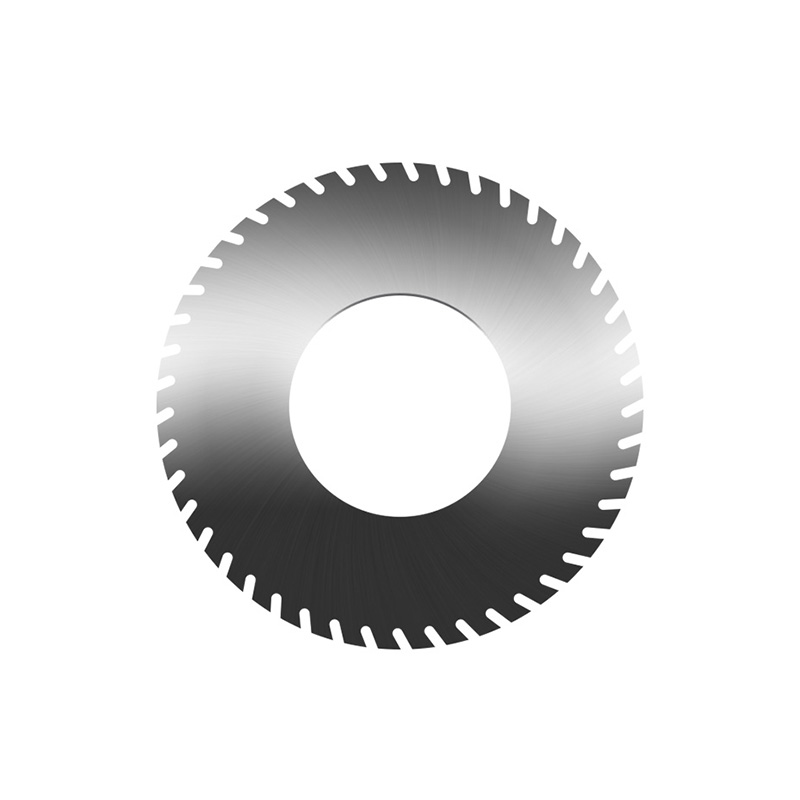

Agnati Tungsten Carbide Cutter Knives Tc Corrugated Cardboard Circular Blades

lehare la agnati circular φ240 * φ115 * 1 mm le sebelisetsoa ho seha pampiri e entsoeng ka masenke.thipa ea slitter e entsoe ka thepa ea tungsten carbide.ho netefatsa boleng, re sebelisa thepa ea mantlha ea 100% e tiileng ea carbide.

re na le feme ea rona ea blade e se nang letho, re etsa vacuum sintering fekthering ea rona.ka lebaka lena, re inshorense boleng ho tloha qalong.

ha ho bapisoa le litšepe tse tloaelehileng (tšepe e sa hloekang, hss, carbon steel).blade ea rona ea carbide e na le bophelo bo bolelele ba ho sebetsa, anti-high-themperature, ho khathala ho phahameng, ho hlaka ho feta, ho nepahala ho phahameng, boima bo phahameng, ho thibela mafome, ho ba tšesaane ho feta.

re moetsi oa ho qetela 'me lehare lena ke tekanyo ea rona e tloaelehileng.re na le setoko se lokiselitsoeng sa lehare lena kamehla.kahoo o ka fumana bongata kamoo o lakatsang mme o fumane theko ea tlholisano hape.ka lebaka la hore re moetsi, re ka fana ka litharollo tse betere ho bareki le ho fana ka litšebeletso tsa oem le odm ho bareki.

-

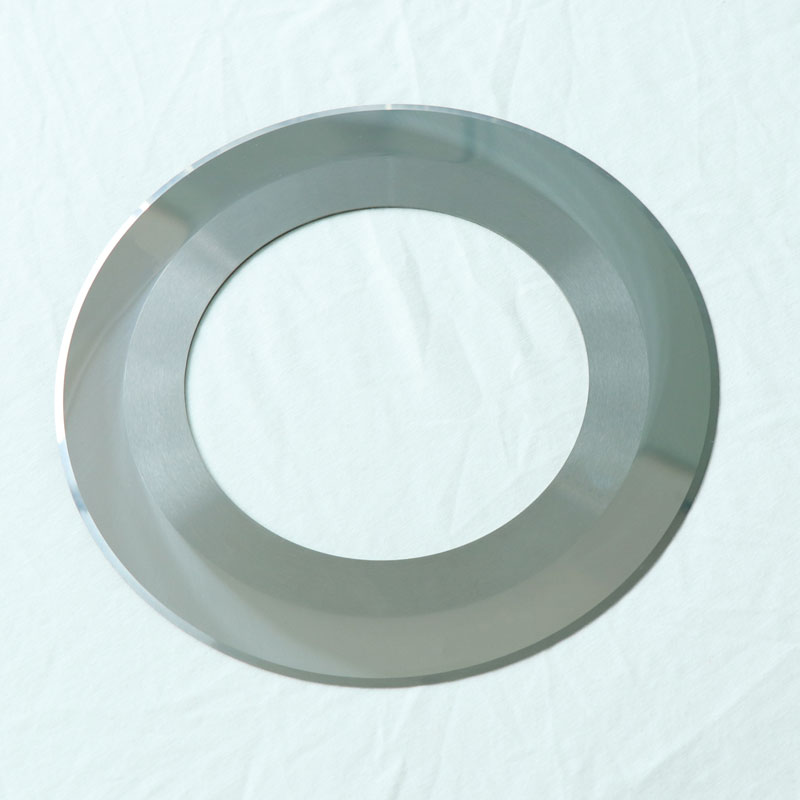

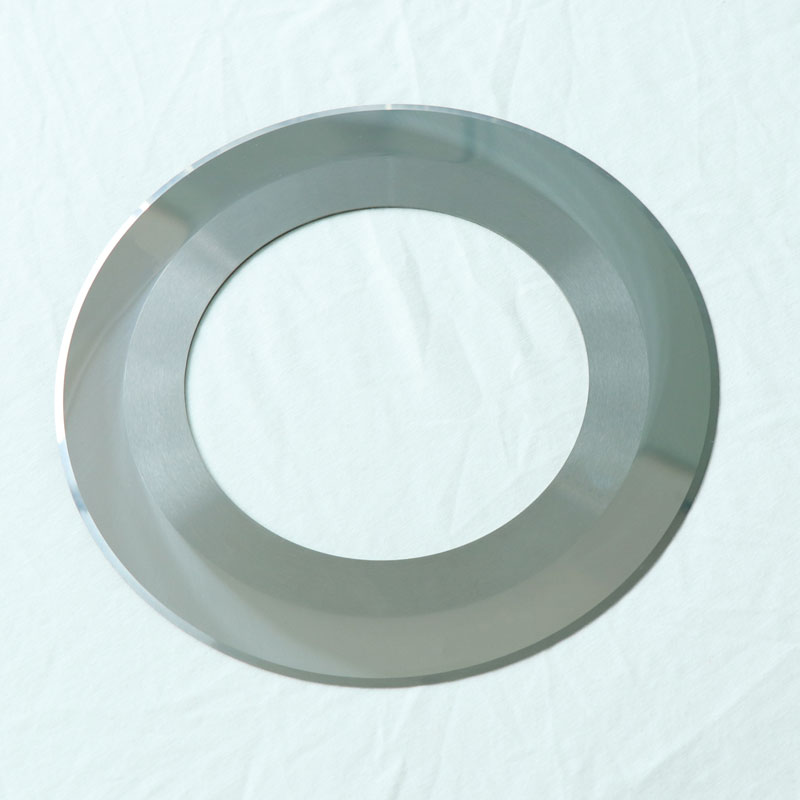

Tungsten Carbide Justu Razor Slitter Lithipa tsa Corrugted Cardboard Circle Blades

Lehare la sliftter 200x122x1.2mm le sebelisetsoa ho seha pampiri e entsoeng ka masenke.thipa ea slitter e entsoe ka thepa ea tungsten carbide.ho netefatsa boleng, re sebelisa thepa ea mantlha ea 100% e tiileng ea carbide.

Re na le feme ea rona ea blade e se nang letho, re etsa vacuum sintering fekthering ea rona.ka lebaka lena, re inshorense boleng ho tloha qalong.

1. ha ho bapisoa le litšepe tse tloaelehileng (tšepe e sa hloekang, hss, carbon steel) blades.blade ea rona ea carbide e na le bophelo bo bolelele ba ho sebetsa, anti-high-themperature, ho khathala ho phahameng, ho hlaka ho feta, ho nepahala ho phahameng, boima bo phahameng, ho thibela mafome, ho ba tšesaane ho feta.

2. bophelo bo bolelele ba tšebeletso, ts'ebetso e phahameng ea litšenyehelo.

3. phello e ntle ea ho itšeha, ho ntlafatsa boleng ba paperboard, ha ho na sebaka sa ho itšeha ka burr, ha ho na mekhoa ea ho sebetsa.

4. ho nepahala ho phahameng le khanyetso e babatsehang ea abrasion.

5. ts'ebetso e tšepahalang (nako e fokolang ea mochini)

-

Tungsten Carbide Milling Insets For Book Binding

Litlhophiso tse khethehileng tsa bevel li fokotsa matla a ho itšeha, li fana ka mokhoa o nepahetseng ka ho fetisisa le ho thibela liphello tsa mocheso, esita le ka li-block tsa libuka le pampiri e thata.PASSION lisebelisoa tsa ho sila li otlolla bokaholimo le ho lokisa liphoso.

-

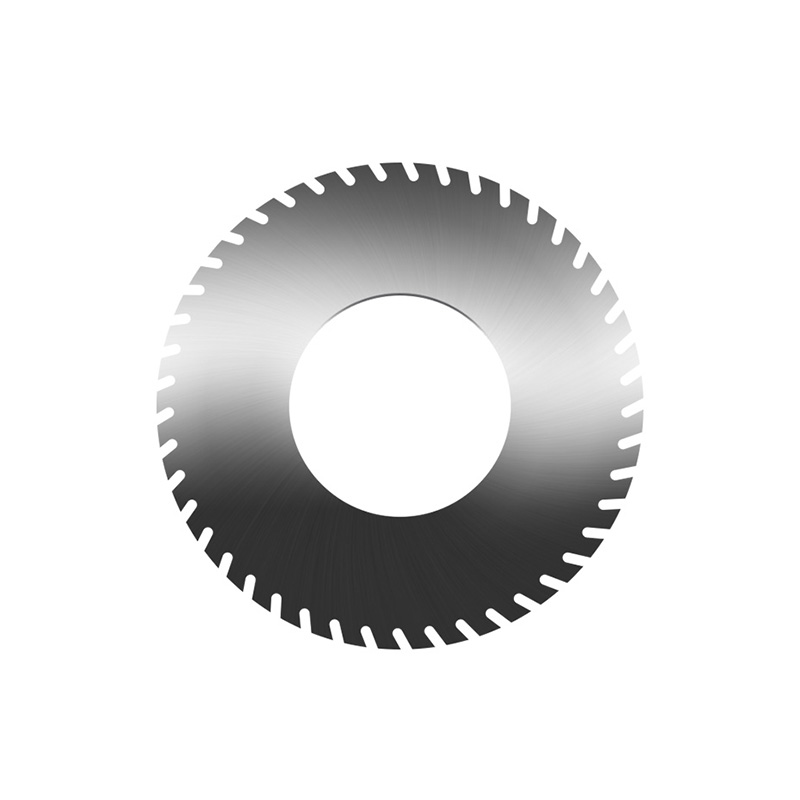

Tungsten Carbide Milling di-blades le lithipa tsa ho phunya bakeng sa indasteri ea khatiso ea rotary

"PASSION" lisebelisoa tsa carbide ke moetsi ea hloahloa oa lehare le tiileng la carbide le nang le meno Chaena.Re na le boiphihlelo ba lilemo tse 15 ba ho hlahisa lehare la sakha la tungsten le nang le meno mme re fumane botumo bo bongata 'marakeng.bophelo ba nako e telele, khanyetso e ntle ea ho apara le boima bo phahameng, stock bakeng sa boholo bo tloaelehileng.Re khetha ka hloko sehlopha se hlokahalang bakeng sa ts'ebetso e nepahetseng ea ho itšeha ho latela lilemo tsa boiphihlelo tšimong.

-

Thipa e Trimmer ea Mahlakoreng a Mararo For Printing Industry

“CHESEHO”—setsebi sa hao sa lithipa tsa indasteri bakeng sa indasteri ea khatiso ea poso.Re fana ka lithipa le lisebelisoa bakeng sa baetsi bohle ba mechini ba tloaelehileng, joalo ka: Polar, Perfecta, Wohlenberg, Schneider Senator le tse ling.

-

Ngaka e seha li-blades For Printing Industry

Mechine ea khatiso ea Flexographic e sebetsa ka motsoako oa "anilox roller" le "inking" ea ngaka e etsang hore ho be bohlokoa hore li-blades tsa ngaka li eketse nako ea bophelo.Ho ipapisitse le ts'ebeliso, li-lamella, li-bevel kapa li-blades tse otlolohileng tse nang le mahlakore a chitja li sebelisoa ho metha enke.Ka lebaka la bokaholimo ba li-roller tsa ceramic anilox, khatello e nyane ea lehare la ngaka e lula e khothaletsoa.Ka kakaretso, moeli o mosesaane oa lehare o lumella ho hlakola ho hloekisa.Ntho ea bohlokoa ka ho lekana bakeng sa bophelo bo botle ba lehare la ngaka ke kamano pakeng tsa tlhophiso ea lisele (sebopeho / palo) le botenya ba ntlha ea lehare.

-

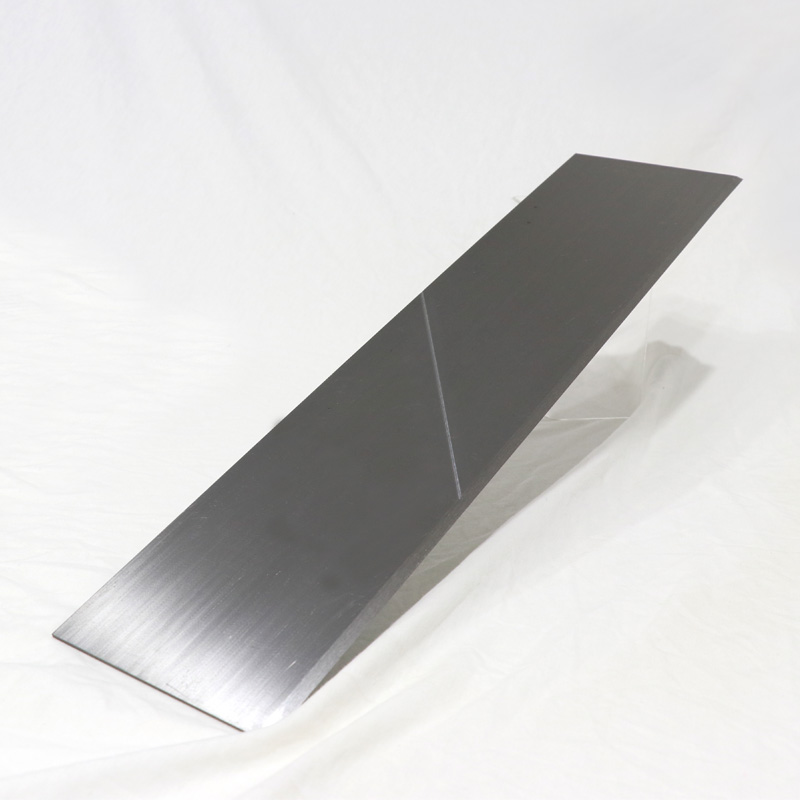

NC sehiloeng di-blades lesenke paperboard Cross cut di-blades

Li-blades tsa rona tsa ho kuta pampiri li sebelisoa haholo-holo bakeng sa ho fetola maqephe.Joalo ka ho fetola pampiri ea masenke, ho fetolela pampiri.

-

Lithipa le Li-Blades tsa Ts'ebetso e Tloaelehileng ea tšepe e se nang tšepe

Li-blade tsa ho lokisa lijo kapa joalokaha ba bang ba bitsa lithipa tsa ho lokisa lijo li sebelisetsoa ho seha mesebetsi e kang ho poma, ho seha, ho seha, ho ebola.Ho khetha mofuta o nepahetseng oa tšepe e sa hloekang bakeng sa ts'ebetso ea ho seha lijo ho bohlokoa haholo ts'ebetsong ea lijo ka lebaka la tlhaho ea asiti ea lijo e lebisang ts'ebetsong ea tšepe e potlakileng, 'me e ka lebisa ho silafatsoa ha lijo ka ho aha oxidation holim'a lehare. .

-

tungsten carbide lehare thipa pentagon lehare bakeng sa Chemical faeba ho itšeha

Lehare lena la tungsten carbide pentagon le nang le likarolo tse 5 tse sehang le entsoe ka 100% e tala ea tungsten carbide.

Li-blades tsohle li na le makhetlo a 8 ho sila e le hore lehare le lule le le bohale ka linako tsohle.

Li-blades ke phekolo ea mocheso ea HRA89-91 bakeng sa matla le ho kenngoa ho thata bakeng sa bophelo bo bolelele ho fihla ho 80% ea bophelo bo tšoarellang nako e telele.