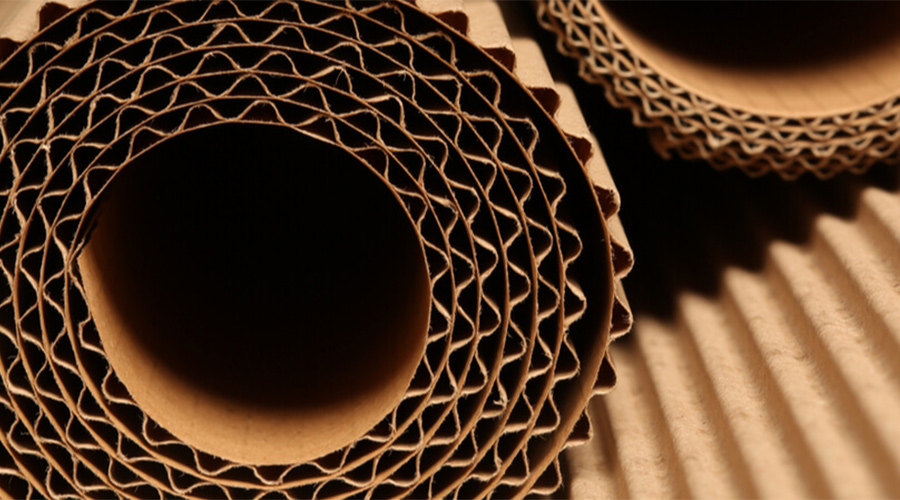

HoIndasteri ea ho paka, tlhahiso le ts'ebetso ea mabokose a makhulo a beha lintho tse ngata tse mabapi le ho hanyetsa ho hanyetsa, ho thata le ho hlafuna ha lisebelisoa. Ha lilemo li ntse li feta, li-carbide tsa tungus li fetohile thepa ea ho khethaLi-li-mashala tse khabisitsoengka lebaka la thepa ea eona e ntle ea 'mele le ea lik'hemik'hale. Sehloohong sena, re sheba hore na ke eng e etsang hore carbide e be letšoele joalo ka khetho e ntle ka ho fetisisa ea likubu tse ngata tse kholo.

Hung Cabide, e boetse e tsejoang e le bothata ba cungsten, na thepa e alimiloeng e entsoe ka ts'ebetso ea metal ea phofo. E na le li-tungsten carbide le cobalt le li-blue tsa tšepe tse ling tse nang le bothata bo botle joalo ka ho hanyetsa haholo, matla a phahameng le li-corrosation tsa ho hanyetsa. Makhoba ana a etsa hore morui oa polasetiki o rekise mabokose a manyane a rekisoang ke mabokose a mangata, ho thata haholo, lintlha tse matla.

Ts'ebetso ea mabokose a enneng e hloka libere ka ho hanyetsa e phahameng haholo. Lisebelisoa tsa mabopo tsa mabota li ntlafetse haholo ho feta thepa ea a setso e kang tšepe e lebelo haholo le tšepe e se nang letsoai. Sena se bolela hore li-tungsten carbide li na le bophelo bo bolelele ba tšebeletso e telele, li bakoang ka mokhoa o fokolang oa nako ea phomolo le tlhahiso e eketsehileng. Bakeng sa indasteri ea liphutheloana, sena se bolela litšenyehelo tse tlase tsa tlhokomelo le tlhahiso e phahameng.

Ho thata le mathata a maholo a carbide le hona joale le ka lebaka la hore e be le thepa e loketseng ho khaola li-brating tsa lebokose. Hardness ke tekanyo ea bokhoni ba thepa ea ho hanela likheo le lithane. Nakong ea sehiloeng ka mabokose a mangata, lehare le hloka ho mamella khatello ea matla le likhohlano le likhohlano. Ho thata ho thatafalloa ha carbide ho phahame haholo ho feta ka nako e 'ngoe ea setso ea ho kuta, e e thusang ho boloka bohale ba bohale bo feta nakong e telele, netefatsa boleng bo bolileng.

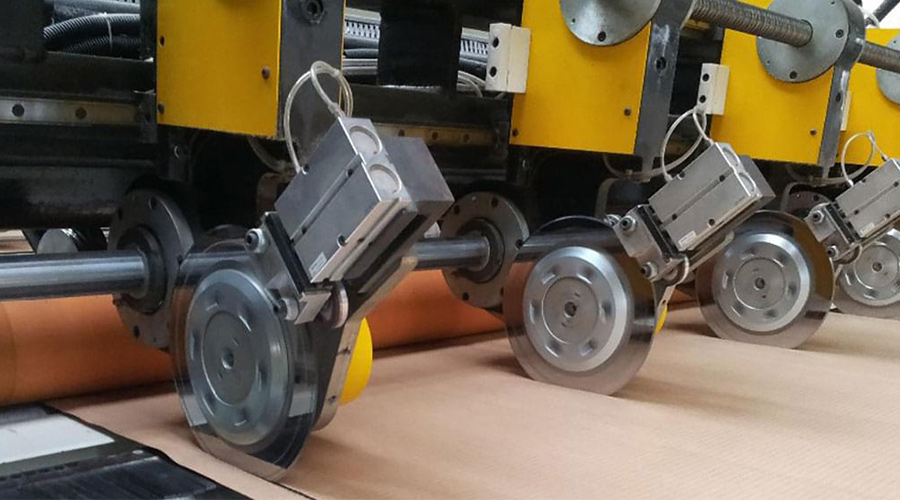

Ntle le ho roala ha ho hanyetsa le ho hanyetsa ha ho hanyetsa le ho thatafala, li-carbide carbide le tsona li na le boits'oaro bo totobetseng. Nakong ea seharui, lehare le hlahisa mocheso, 'me haeba mocheso o sa khone ho nyehela ka nako, e tla lebisa ho sejong sa lehare le ho kokobela bohale. Ho kenella ha lithapo tsa tukten ho thusa ho fokotsa phello ea ho kuta nakong ea ho seha, ho boloka botsitso ba lehare le ho fokotsa ho nepahala.

Thunya ea carbide e boetse e khona ho fihlela qeto e sebetsang le e hlakileng ea ho fokotsa litlamorao nakong ea ho seha ts'ebetso ea lebokose le koahetsoeng. Sena se bohlokoa ho thibela boitsebiso hore li ka arola lipakeng tsa likarolo kapa ho phatloha ka metheong. Haholo-holo ho Theknoloji ea Ultrasonic, ts'ebetso e ntle ea ho ts'oaroa e fuoang papali e felletseng, hape e ntlafatsa ts'ebetso ea kakaretso ea ho kuta.

Ka kakaretso, li-carbide tsa tungsten ke thepa e ntle ka ho fetisisa bakeng saHo khaola pampiri e halikiloengKa lebaka la thata ea eona e matla, ho hatalla ho phahameng, ho hanyetsa ho hoholo ho feta, matla a mangata le ho ba le boitšoaro bo botle bo phahameng. Ha e ntlafatse litšenyehelo tsa tlhahiso ea tlhahiso feela 'me ha e emise litšenyehelo tsa tlhokomelo, empa hape e netefatsa hore boleng bo abile le ho nepahala. Ka nts'etsopele e tsoelang pele ea moralo oa lehare le mahlale a liphoofolo, ts'ebeliso ea li-tungsten carbide indasteri e pharaletseng, e fana ka tharollo e ntle le ts'ebetso e ntle le e nepahetseng.

Hamorao, re tla tsoela pele ho ntlafatsa tlhahisoleseling, 'me u ka fumana leseli le lengata webosaeteng ea rona (Passiontool.com) Blog.

Ho joalo, u ka ela hloko mesebetsi ea rona ea sechaba: