Sehloohong se fetileng, re buile ka bohlokoa baSlitter Blades Bokhabane, le mokhoa o motle ka ho fetisisa oa ho eketsa bophelo ba lits'ebeletso tsa slitter ke ho boloka Expch. Kajeno, re tla tsoela pele karolo ea boraro le ea ho qetela ea tataiso ea ho qetela hoLi-blade tsa mochini.

Lits'ebetso le tsoelo-pele ho Blade Blade Blade Blade Blade

Tsoelo-pele ea Bluepter Blade e lebisitse ho nts'etsopele ea tharollo e ntlafalitsoeng e hlahisang ts'ebetso e ntlafalitsoeng le katleho. Boqapi bo bong bo ratehang ke ts'ebeliso ea li-blake tsa carbide - tse fanang ka pherekano ea ho tšoarella le ho roala khanyetso ha e bapisoa le li-blade tsa setso. Carbide-tipped blades are ideal for cutting abrasive materials and can maintain sharpness over a longer period, reducing the frequency of blade sharpening.

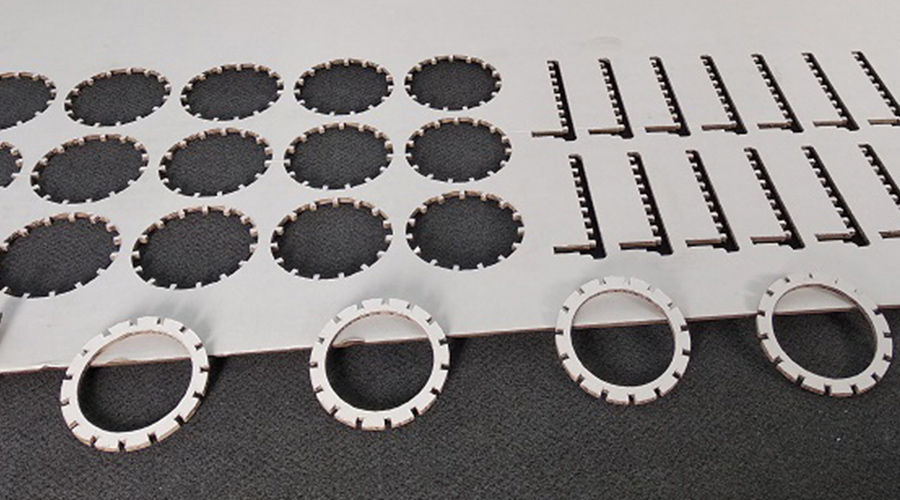

Tsoelo-pele e 'ngoe ea theknoloji ke sebaka sa Theknoloji ea Laser ea Laser ea Laser ea Bengdes, e nolofalletsa ho seha mekhoa e rarahaneng le libopeho tse rarahaneng. Li-Blades tsa Laser li fana ka nepo e phahameng le mekhabiso e hloekileng, e etsang hore li hloke lisandary, joalo ka lisebelisoa tsa motlakase. Ts'ebeliso ea theknoloji ea laser e boetse e lumella lebelo le lefulang le sehiloeng ka potlako le ho fokotsa litšila.

Ntle le litabatabelo tsa boitsebiso le ho hatisa, ho pheta-pheta mananeo a boqapi le lits'ebetso tsa thepa ho se ho thusitse nts'etsopele ea litsebi tsa ts'ebetso ea ts'ebetso. Li-blades tse nang le likokoana-hloko tse ikhethang, tse kang khabone (dlc) likotlo tse eketsehileng, fana ka mathata a ho hanyetsa le ho fokotsa nako ea ho eketseha. Tsoelo-pele tsena tse fumanehang ho Setjitter Blade Blade li ntse li sutumetsa meeli ea ho fokotsa katleho le boleng, ho fihlela lits'ebetso tsa bona tse phahameng.

Ho khetha li-blue tsa shrter tse nepahetseng bakeng sa litlhoko tsa hau tse khethehileng

Ha u khetha litlhokahalo tsa hau tse remang tse tebileng, ho bohlokoa haholo ho nahana ka lintho tse kang mofuta oa boitsebiso bo sehiloeng, 'nete ea ts'ebetso e hlokahalang. Mefuta e fapaneng ea lisebelisoa e ka batla mefuta e ikhethang ea li-geomete e kholo ho fihlela liphetho tse sa khaotseng. Mohlala, lisebelisoa tse kang pampiri le filimi li kanna tsa hloka hore li-racher meleor bakeng sa likhahla tse hloekileng, ha o khona ho hlonepha ka rabara ka ho kuta marikhoe ka ho kuta.

Sepheo se lakatsehang se sekisitseng le sona se bapala karolo ea bohlokoa ho khetha li-blue tse nepahetseng. Ho latela boemo ba ho nepahala ho hlokahalang bakeng sa lits'ebetso tsa hau tsa ho kuta, u ka khetha lijo tse nang le lijalo tse ikhethileng tse ka tsamaisang likhaba tse nepahetseng kamehla. Ho nahana ka lebelo la tšebetso ea ho seha ho bohlokoa hape, joalo ka lebelo le se le boima le sehiloeng ka potlako le ho tšoarella ho lula u ntse u cheka ts'ebetso ea nako.

Ntle le mofuta oa lintho tse bonahalang, ho seha mokhoa, ho rema ka lebelo, ho bohlokoa hore re ka khetha lintho tse ling tse kang ho akheha. Ho khetha li-blade tse entsoeng ka lisebelisoa tsa boleng bo holimo 'me ho na le maemo a thata a thata a thata a ka ntlafatsa ho seha ts'ebetso le bophelo bo bolelele. Manyala a nang le likokoana-hloko tse ikhethang, tse kang Titanium nitride (TIN) bokhelohi, ba fana ka likhakanyo tsa ho hanyetsa mme ba ka khona ho khathala. Ka ho hlahloba ka hloko litlhoko tsa hau tse sa tobang le ho nahana ka lintlha tsena, u ka khetha limela tse nepahetseng tse fihlelang litlhoko tsa hau mme u behe ts'ebetso ea ho kuta.

Sephetho le menahano ea ho qetela

Ha re phethela, slitter Blades ke tlhokeho ea lisebelisoa tse rekisang karolo ea bohlokoa indastering ea bohlokoa ea indasteri e fapaneng, ho tloha sephutheloana ho masela. Ho utloisisa mefuta e fapaneng ea li-stald tse fumanehang, likopo tsa bona le lintlha tseo u lokelang ho li nahana ka ho fihlela sephetho se nepahetseng le ho hatisa katleho. Ka ho etelletsa pele ho sithabetsa, ho hlokomela le ho hlokomela lintho ka nepo, u ka lelefatsa bophelo ba bo-sjed le ho netefatsa ts'ebetso e sa fetoheng.

Lits'ebetso tse fumanehang ho slight Blueter Blade Tsoela Pele ho khanna tsoelo-pele ea ho fokotsa katleho le katleho, ho ntlafatsa mesebetsi ea bona e bakileng. Ka ho latela mekhoa e metle bakeng sa ho boloka litšebeletso le ho khetha litlolo tse nepahetseng tsa litlhoko tsa hau, fokotsa litšila tsa thepa, 'me u ntlafatse tlhahiso ea hau ka kakaretso.

Lefatšeng le ntseng le iphetola le e sa tsoakoang le mealo ea li indasteri, ho tlosa bohale ba ho seha ka botlalo le tataiso ea ho lula e le lefeela le ho fihlela phetheho. Ka tsebo le litakatso tse fumanoeng ho tataiso ena, o hlometse ho etsa liqeto tse nang le tsebo le ho phahamisa ts'ebetso ea hau e rekileng ho Hefurs. Kahoo, amohela lefatše la li-blot tsa stter, hlahloba menyetla eo ba fanang ka eona, 'me u notlolla pheletso e sehiloeng ka mokhoa oa hau oa tlhahiso.

Haeba u hloka lehare lena kapa u na le lipotso ka eona, u ka ikopanya le rona ka kotloloho.

Hamorao, re tla tsoela pele ho ntlafatsa tlhahisoleseling, 'me u ka fumana leseli le lengata webosaeteng ea rona (Passiontool.com) Blog.

Ho joalo, u ka ela hloko mesebetsi ea rona ea sechaba:

Nako ea poso: Jul-26-2024