Sehloohong sa ho qetela re ithutile hore ho sebelisoa ha CNC seqholle ka lindastering ea indasteri e se nang likhoebo tse lokelang ho nkuoa ha re khetha li-knif. Kajeno, re tsoela pele ho hlalosa hore na re ka boloka le ho hlokomela CNC Knife Blades le joang ba ho reka boleng bo holimoCNC BANDESS.

Mokhoa oa ho boloka le ho hlokomela CCN Knife Blades

Tlhokomelo e nepahetseng le tlhokomelo e bohlokoa bakeng sa ho nka bophelo le ts'ebetso ea CNC Knif Blades, e netefatsa boleng le katleho e sa fetoheng le katleho. E 'ngoe ea mesebetsi ea tokiso ea bohlokoa ea tlhokomelo e ntse e hloekile ebile e lokolohile ho ba maloanlahla, joalo ka ha e le hantle ho ka ama ts'ebetso ea ho roala le ho feta. Lekola lehare ka matšoao a tšenyo, joalo ka li-chips kapa li-dull, li bohlokoa bakeng sa ho tseba mathata pele le ho thibela mathata a maholo a maholo.

Karolo e 'ngoe ea bohlokoa ea tlhokomeliso ea ho boloka li le hantle e tšosa le ho sebelisa lehare ka moo ho hlokahalang ho boloka bohale ba eona bo bokoang le katleho. Ho sebelisa lisebelisoa le mekhoa e metle e matla ea bohlokoa bakeng sa ho boloka tikoloho ea li-goomet ea lehare le ho netefatsa ts'ebetso e tiileng. Ntle le moo, ho kopanya lehare le ho fetola lipara ho ea ka thepa ea lintho tse bonahalang ho ka thusa ho lelefatsa bophelo ba Leha ho le joalo le ho lula u senyeha.

Ho boloka ka nepo ho CNC senipa ho boetse ho bohlokoa ho thibela tšenyo le ho boloka lintho tse mpe tsa bona. Ho boloka li-blanse tsa tikoloho e hloekileng, e omileng hole le mongobo le liithuti li ka thusa ho holisa bophelo ba bona le ho boloka boleng ba bona bo bofu. Ho bohlokoa ho sebelisa sekoaelo kapa linyeoe tse sirelelitsoeng kapa ho sireletsa limela ho tsoa lerōle le lintho tse ling tse ka ama tšebetso ea bona. Ka ho latela mekhoa ena ea tlhokomelo le ho hlokomela CNC Knif Blades, bahlahisi ba ka eketsa ho phela nako e telele le katleho ea lisebelisoa tsa bona tse remahetseng.

Moo ho rekang CNN Kniipe Blades

Ha u sheba ho reka li-CNN tsa boleng bo holimo-limona bakeng sa litlhoko tsa hau tsa tlhahiso, ho bohlokoa ho e ntša maikutlo le bahlahisi ba bulang le bahlahisi ba bona. Likhamphani tse ngata tse ikhethang li fana ka khetho e ngata ea CNC Knii e kenella likoting le lisebelisoa tse fapaneng tse sehiloeng bakeng sa litlhokahalo tse nepahetseng. Hangata, barekisi bana ba fana ka tlhaiso-leseling e qaqileng, ho kopanyelletsa le litlhaloso tse ngata, thepa le ho ikemela, ho u thusa ho etsa liqeto tse ba boleloang.

Mabenkele a marang-rang a marang-rang le mabenkele a phepelo a indasteri a reka mehloli e tloaelehileng ea ho reka li-cnc Knish mehloling ea CNC Kniphes ho tsoa ho bahlahisi ba fapaneng ba tsoang ho bahlahisi ba fapaneng. Ntle le moo, ho fihlela Baetsi ba mochini oa CNC kapa barekisi ba ka fana ka leseli la bohlokoa le likhothaletso tsa boleng bo holimo bakeng sa litlhoko tsa mochini oa hau o ikhethileng oa mochini le litlhoko. Ka ho buisana le litsebi tsa indasteri le ho hlahloba barekisi ba fapaneng, u ka fumana bareki ba boleng bo holimo ba ka fumana li-cnc.

Pele u reka, ho bohlokoa ho hlahloba litlhahlobo tsa bareki le bopaki ho lekola boleng le ho ts'epahala ha CNC Knif ho etsoa ke barekisi ba fapaneng. Litlhahiso tse tsoang ho basebelisi ba bang li ka fana ka leseli la bohlokoa ts'ebetsong le ho tšoarella ha majabajaba, ho u thusa ho etsa qeto. Ntle le moo, nahana ka lintho tse kang litheko, likhetho tsa lits'ebetso le lits'ebeletso tsa tšehetso ea bareki ho netefatsa hore ho rema thepa ea hau ea CNC Knife Blade.

Haeba u na le litlhoko, u ka boela ua ikopanya le rona. Re boetse re hlahisa mefuta e mengata ea li-cncni tsa boleng bo phahameng tsa CNC. Kapa u na le lipotso kapa u batla ho fumana thuso, re ka u araba.

Sephetho: Ho khetha le letona la CNN Snife Blade bakeng sa litlhoko tsa hau

Qetellong, CNC thanife Blades ke lisebelisoa tsa bohlokoa tsa ho khaola le ho rala mesebetsing e seng molaong le ts'ebetso ea ts'ebetso ea boitsebiso. Ka ho utloisisa mefuta e fapaneng ea CNC Kniphe Brul

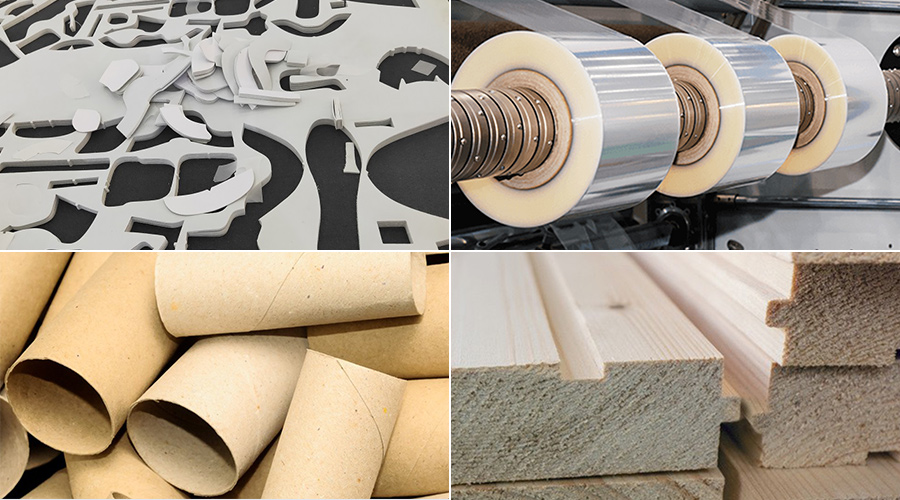

Ho khetha CCN Knife Blade ka lebaka la litlhoko tsa hau tse ikhethileng li kenyelletsa ho hlahloba lintlha tsa lintho tse bonahalang, ho fokotsa le moralo oa metsi ho netefatsa ts'ebetso e nepahetseng le katleho. Ka ho hlahloba lintlha tsena le ho latela mekhoa ena ea tlhokofatso, bahlahisi ba ka lelefatsa bophelo ba CNC Knif ba Blades mme ba lula ba fa boleng ha nako e ntse e tsamaea. Hore na o beoa patsi, polasetiki, tšepe kapa likuka, ho khetha seretse se nepahetseng sa CNN Knife ho hlokahala bakeng sa ho fihlela ho nepahala le ts'ebetso ea tlhahiso.

Lenaneong le ntseng le hlahisa sebaka se seng le se etsahalang, C4 Ka ho sebelisa matla a ka botlalo a CNC Kniphe Blades le Khohlano, bahlahisi ba ka phahamisa tsebo ea bona e ncha le ho fana ka lihlahisoa tse ikhethang tse khotsofatsang 'marakeng oa kajeno. Ka tsebo e nepahetseng, lisebelisoa le boiphihlelo, tse sebelisang tsebo ea CNC CNC CNCE ka thipa

Ke eona kaofela bakeng sa sengoloa sena. Haeba u hloka senaCNC Knife BladesKapa u na le lipotso ka eona, u ka ikopanya le rona ka kotloloho.

Hamorao, re tla tsoela pele ho ntlafatsa tlhahisoleseling, 'me u ka fumana leseli le lengata webosaeteng ea rona (Passiontool.com) Blog.

Ho joalo, u ka ela hloko mesebetsi ea rona ea sechaba:

Nako ea poso: Sep-06-2024