Sehloohong sa ho qetela re ithutile hore na ho na le theknoloji ea CNC le Mefuta e fapaneng ea CNC Knif Blades. Kajeno, re ntse re tsoela pele ho hlalosa kopo ea CNC Kniphe Maries, lintlha tse lokelang ho nahaneloa ha li khetha li-cnc. Blades le Melemo eaCNC Knife Blades.

Likopo tsa CNC Knife Blades Induesry

Ho fapanyetsana le ho shebella ha Cnc thani ea maiketsetso ho bona lisebelisoa tsa bohlokoa indastering e fapaneng, moo ho betliloeng ke lintho tsa bohlokoa. Indastering ea maletsi, CNC Knife Blades e sebelisoa bakeng sa ho seha lisebelisoa tsa patsi ho theha thepa ea moetlo, khabinete le likarolo tsa khabinete le likarolo tsa khabinete le likarolo tsa khabinete le likarolo tsa khabinete le likarolo. Bokhoni ba ho fihlela meralo e rarahaneng le li-degni tse boreleli li etsa hore CNC Knif e atereha e tukang har'a lithuno tsa boleng bo holimo le ho nepahala.

Pagnage le indasteri ea litšoantšo, CNC Knii o ile a bapala karolo ea bohlokoa ea ho seha vinyl, ea foam le lisebelisoa tse ling tse sebelisitsoeng ho tlhahiso ea matšoao. Bokhoni ba ho fokotsa litlhaku tse nepahetseng, libopeho le li-logot tse hloekileng le libaka tse boreleli li etsa hore CNC Knii o loketse ho theha matšoao le lipontšo. Lebelo le ho nepahala ha mechini ea CNC mechini e nang le li-kniphe Blades tse lumellang litšoantšisang tsa matšoao a ho hlahisa lihlahisoa tsa boleng bo holimo le ka nepo.

Liindasteri ea likoloi le Aerospace, CNC Knif li sebelisetsoa li-garts tse sehiloeng, litiiso le lisebelisoa tse kopaneng. Bokhoni ba ho mamella le ho mamella ka mokhoa o thata le libopeho tse khahlang ke tsa bohlokoa likarolong tsena, moo lisebelisoa tse thata tsa tšebetso le tsona li tloaelehile. CNC Knipho Blades e fana ka ho nepahala le ho ts'epahala tse hlokahalang ho fihlela lits'ebetso tse thata tsa likotlo tsa likoloi le aerospace lihlahisoa tse felisitsoeng.

Lintlha Tseo U ka li nahanang ha u khetha CNC Knife Blad

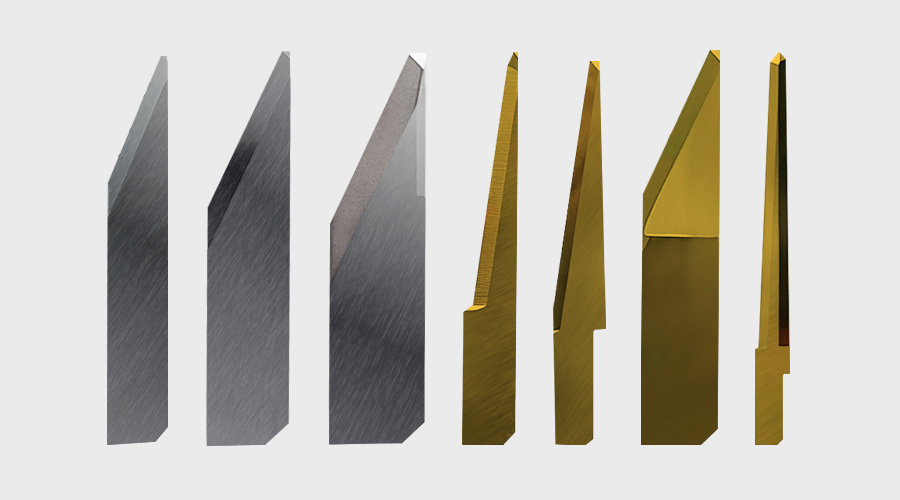

Ha u khetha moholi oa CNC ho na le ts'ebeliso e itseng ea ts'ebeliso e itseng, ho lokela ho nkuoa lintlha tse 'maloa ho netefatsa ts'ebetso e nepahetseng le katleho. Ntho e 'ngoe ea bohlokoa ke hore litaba li khaoloe, ha thepa e fapaneng e hloka mefuta e itseng ea lijo le ho fokotsa lipara ho fihlela likuma tse hloekileng le tse nepahetseng. Mahlomola a thata joaloka litloaelo a ka hloka hore a ka bereide kapa a koahetsoeng ke daemane bakeng sa ho kuta ka katleho, ha thepa e sootho e ka khaoloa ka thata ka tšepe e thata.

Ntho e 'ngoe ea bohlokoa ea bohlokoa eo u lokelang ho e nahana ke lebelo le sehiloeng le sekhahla sa ho fepa, se khethollang sekhahla seo lehare se tsamaeang ka sona. Ho lokisa liparasi tsena ho latela thepa ea thepa ea thepa le li-gade ho bohlokoa bakeng sa ho fihlela lits'ila tse boreleli le tse nepahetseng. Ho feta moo, ho jaloa ha banna le bohale ho bapala papali ea bohlokoa ts'ebetsong, maemo a susumetsang a ho rema, maemo a kang a ho khaola.

Moralo o akaretsang oa ka kakaretso le kaho ea CNC Knife e boetse e ama ts'ebetso ea eona le ho phela nako e telele. Lintho tse kang ho betla matla, ho jala sekhutšoane, 'me boleng ba lintho tsa lintho tse bonahalang bo ka ama tsela ea ho tšoarella le ho fokotsa tsela. Ho khetha lehare ka ho kopanya lintho tsena ho bohlokoa ha lintlha tsena ho bohlokoa bakeng sa ho eketsa tlhahiso le ho fihlela sephetho se fetohang. Ka ho hlahloba lintlha tsena ka hloko le ho khetha blati e kenang e nang le litlhokahalo tsa morero, bahlahisi ba ka ntlafatsa mekhoa ea bona ea ho seha mme e ntlafatsa boleng ba tlhahiso.

Melemo ea ho sebelisa CNC Knife Blades

Ts'ebeliso ea CNC Kniphe Blades e fana ka menyetla e mengata bohatong ba ho etsa thepa, e ba etsang lisebelisoa tse sa sebetseng tsa ho khaola le ho ba le mesebetsi. E 'ngoe ea melemo ea bohlokoa ea CNC senipa Blades ke bokhoni ba bona ba ho tlisa likuku tse lumellanang le tse nepahetseng, e netefatsang tse nepahetseng le boleng lihlahisoa tse felisitsoeng. Taolo e nepahetseng e fanoang ke mechini ea CNCine ho fihlela mekhoa e rarahaneng le sebopeho se rarahaneng habonolo, ho ntlafatsa li-aesthetics le ts'ebetso ea lihlahisoa tsa ho qetela.

Monyetla o mong oa ho sebelisa CNC Kniphe Blades ke katleho le tlhahiso le tlhahiso tseo ba li etsang mosebetsing oa tlhahiso. Ka ho alima mesebetsi le ho tlosa liphoso tsa matsoho, cnc mechine ea CONE e nang le melapo ea thipa e ka fokotsa nako le litšenyehelo ha u ntse u eketsa libuka. Tsela e phahameng ea ho khaola le ho nepahala ha CNC Kniphe Blades e thusa bahlahisi ba ho phallela lits'ebetso tsa bona ebe ba etsa qeto ea ho sekisetsa boleng.

Ho feta moo, Cnc thanife ea CNC e fana ka mefuta e fapaneng ea ho khaola thepa e kholo, ho tloha libakeng tse bonolo ho ea matlong le liqapi. Ho fapanyetsana lintho tsena ho fa sesebelisoa le lisebelisoa tse le leng ka sesebelisoa sa motho a le mong, fokotsa tlhokahalo ea ho kenya lisebelisoa tse ngata tse rehang. Hore na u se eka mekhoa e rarahaneng ea Acrylic

Ke eona kaofela bakeng sa sengoloa sena. Haeba u hloka senaCNC Knife BladesKapa u na le lipotso ka eona, u ka ikopanya le rona ka kotloloho.

Hamorao, re tla tsoela pele ho ntlafatsa tlhahisoleseling, 'me u ka fumana leseli le lengata webosaeteng ea rona (Passiontool.com) Blog.

Ho joalo, u ka ela hloko mesebetsi ea rona ea sechaba:

Nako ea poso: Aug-28-2024