Mokhoa oa ho kopanya

Hajoale, mekhoa e ka sehloohong e sebelisoang hangata ke deposition ea lik'hemik'hale (CVD) le Tekanyetso ea Mocheso e ka tlase e le Deposition (PCVD)

(1)CVD (COPOIZY VUSPIZY)

USing mouoane, hydrogen le likarolo tse ling tsa lik'hemik'hale tsa li-halideBladesubstrate. Ts'ebetso ea CVD e na le mocheso o phahameng, oa ho bolokoa ka botšepehi, empa o ka hlahisa mathata a joalo ka likhatello tse sa feleng tsa teropo.

(2)Pvd (Tekanyetso ea mouoane oa nama)

Tlas'a maemo a ho phomola, voltage e tlaseBladesubstrate e sebelisa phello e potlakileng ea tšimo ea motlakase. Mocheso oa PVD o na le mocheso o tlase (300 ~ 500 ° C), e ke keng ea senya bothata le ho nepahala haBladeSubstrate, 'me koae e na le bohloeki le menyako,' me e boetse e le hammoho le substrate.

(3)PCVD (plasma lik'hemik'hale tsa lik'hemik'hale tsa lik'hemik'hale tsa plasma)

Ho sebelisa plasma ho khothaletsa karabelo ea lik'hemik'hale le ho fokotsa mocheso oa koae ho ka tlase ho 600 ° C. E loketse liketsahalo moo ho fapaneng kapa ho fapanyetsang karabelo ea karabelo lipakeng tsa tlhahlobo ea carbide e halikiloeng le thepa e koahelang.

(4)Ibad (ion Beam e thusitsoe ka theknoloji ea maemo)

Ha a ntse a beha koae ka karolo e batang e tsoelang pele e behiloeng ka mokhoa o tsoelang pele ka beam ea matla a itseng ho ntlafatsa matla a bolotsana lipakeng tsa koae le substrate.

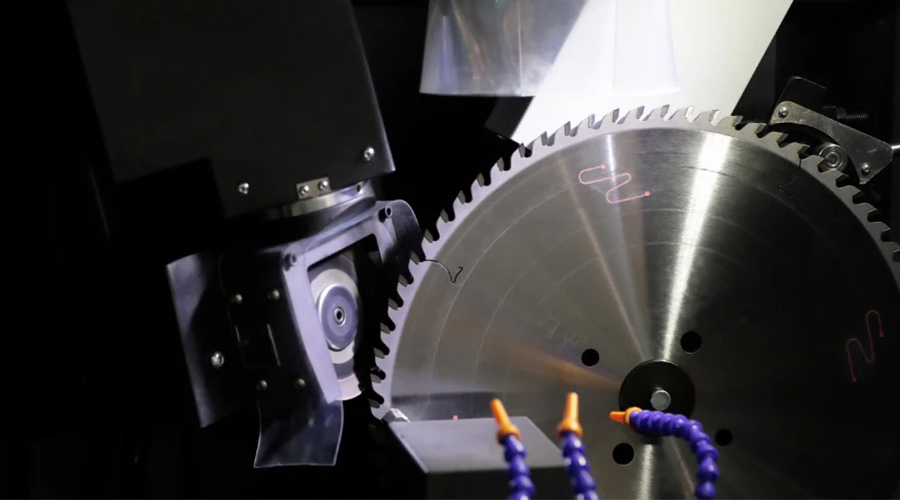

Melemo ea koaeBlades

lU ITHUTA HO ITHUTALingoloa tse nang le thata li na le thata haholo 'me u apare ho hanyetsa, ho holisa haholoBladeBophelo.

lHo hanyetsa ho ntlafatsoa ha oxidation: TO apere e le mokoallo oa lik'hemik'hale, oa khoepesa, ho fokotsa bohato ba ho fokotsa le liphetoho tsa lik'hemik'hale pakeng tsaBladele mosebetsi o mongata.

lE fokotsehile: CLits'oants'o li na le semelo se tlase, se atlehileng se seha sa seha sa seha.

lEketsa Takatso ea Tekanyo ea Metal: Lisebelisoa tse koahetsoeng ka nepo ha li hana katoloso e tsamaeang ka letsoho.

lEketsa khanyetso ea ho tsitsipana: THo na le lintho tse bonahalang tseo a kopaneng le tsona li na le botsitso bo botle ba ho kuta mme ba ratana le mocheso o phahameng oa mocheso.

lE thibela Corrosion: Ho bakoa ho ka ba bothata bo tebileng, haholo-holo bakeng sa maqeba a sesole le boleng bo phahameng, bo entsoeng hantle bo ka fokotsa lintho tsa ho hlokomela haholo le kotsi ea moqomo.

Holisa bophelo ba sehlahisoa: BLikotsi tsa thomello li ka ntlafatsa ho tšoarella, ho senya ho hanyetsa ts'ebetso ea metsi, 'me lehare le nang le metsi le letona a ka thusa ho holisa bophelo ba indasteriBladeS, e bohlokoa bakeng sa ho fokotsa nako ea phomolo le ho ntlafatsa katleho.

U hloka ho nahana ka lintlha tse latelang pele u khetha lehare la hooa

(1)Ts'ebeliso ea sehlahisoa

Pele, ho bohlokoa ho tseba hore na sehlahisoa se tla sebelisoa hokae, joalo ka ts'ebetso ea lijo, e leng lisebelisoa tsa phaello. Ticn le Teflon e na le likheo tse ntle tse se nang chefo le FDA. Haeba indasteri ea hau e hloka limela tse feto-fetohang, makhapetla a DLC le chrome ka thata ke khetho e ntle haholo.

(2)Etsa bonnete ba hore li-blades ke boleng bo phahameng

Ntle le ho batla boleng ho moetsi, o hloka ho etsa bonnete ba hore lithipa tsa hau ke boleng bo holimo pele u sebelisa koae. Leha e le ho koaheloa ka sekhahla se phahameng, lehare le tlase le ke ke la tšoarella nako e telele haholo, 'me sena se ka ama katleho ea koana. Haeba u batla ho etsa hore ho be le makhapetla a mangata, o hloka ho etsa bonnete ba hore o qala ka lithipami tsa boleng bo holimo.

(3)Litlhoko tsa ts'ebetso

Tsena li kenyelletsa ho thatafala, ha ho hanyetsa a ho heletsa, ho hanyetsa mocheso o phahameng, ho hana mocheso o phahameng, litlhoko tsena tsa ts'ebetso ho tla khetholla mofuta oa ho koaloa.

(4)LITLHAKISO TSA BOPHELO

Litšenyehelo tsa mekhoa ea ho koahela le ho ikamahanya le tsona le tsona li boetse li sebetsana le litaba tsa bohlokoa ha u khetha.

Sephetho

BladeTheknoloji ea ho qala ke tsela e sebetsang ea ho ntlafatsaBladeTs'ebetso, holisaBladeBophelo, botlante bo ntlafatsang boha katleho le ho nepahala ha ho na le mochini. Ka khetho ea lisebelisoa tse loketseng tsa ho koahela le mekhoa ea ho ikamahanya, koaeBladeS ka ts'ebetso e ntle e ikhethileng e ka lokisoang ho fihlela litlhoko tse fapaneng tsa ts'ebetso ea ts'ebetso ea ts'ebetso ea ts'ebetso ea ts'ebetso. Nakong e tlang, ka ntso e tsoelang pele le nts'etsopele ea theknoloji ea koae, koaeBlades o tla bapala karolo ea bohlokoahali indastering ea ho etsa tlhahiso.

Ke tsohle bakeng sa sengoloa sena. Haeba u hloka THEindasteri Blades Kapa u na le lipotso ka eona, u ka ikopanya le rona ka kotloloho.

Hamorao, Re tla tsoelapele ho ntlafatsa tlhaiso-leseling, 'me u ka fumana leseli le lengata webosaeteng ea rona (- Passiontool.com) Blog.

Ho joalo, u ka ela hloko mecha ea rona ea sechaba:

Nako ea ho romella: Oct-18-2024