Lefats'eng la tlhahiso Ho tloha mapolanka ho fihlela patsi, le lipolanete ho ea ho likhoka, ho seha lisebelisoa li bohlokoa bakeng sa ho hlapa, 'me li qeta thepa e ngata. Har'a lisebelisoa tse fapaneng tse sebelisoang ho etsa lisebelisoa tsena, li-tungsten carbide (wc) li ntlafatsa haholo ts'ebetso ea ho seha lisebelisoa.

Tungs Carebide ke boitsebiso bo thata, bo hanyetsang bo entsoe ka tungstern le li-athomo tsa khase li tlamohile sebopeho sa kristale. Mefuta ena e ikhethang e fa tungsten ea ho kenya mathata a eona a tsotehang le ho le thata, e e etsa khetho e ntle bakeng sa ho ngola lits'ebetso tsa sesebelisoa.

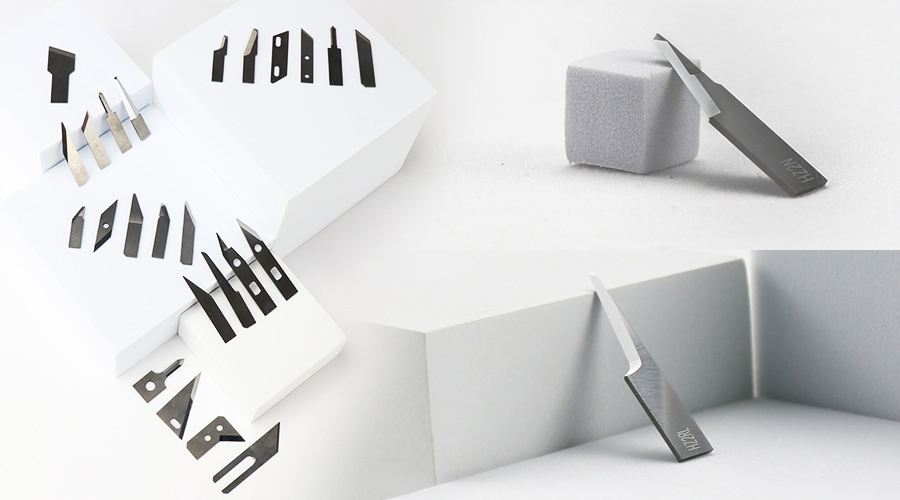

E 'ngoe ea litsela tsa ka sehloohong li-carbide tsa ho khaola li ntlafatsa ho fokotsa ts'ebetso ea sesebelisoa e ka thata haholo. Ka tekanyetso ea thata ea li-harmols litaemane,Hungsten Carbide Blades'me malebela a ka mamella likhatello le likhohlano tse tebileng nakong ea ho seha. Sena se ba lumella ho boloka theko ea bona e le ngata nako e telele, e fokotsa khafetsa ea ho chesa le ho lokisa sesebelisoa.

Ntle le thata, ho hanyetsa ha kharale ea carbide carbide ke ntho e 'ngoe ea bohlokoa ea ho ntlafatsa ts'ebetso ea sesebelisoa. Roala ho hanyetsa ho bua ka bokhoni ba ho fana ka ho tlosoa ha eona ka lebaka la ketso ea mochini, e kang likhohlano kapa ahlaka. Ts'oara ea Carbide Carbide Carbide Carbide e netefatsa hore ho lula matloana a tsona ea pele le boholo ba tsona, le kamora nako e telele. Liphetho ena ea sesebelisoa ho geometry ea sesebelisoa li lebisa liphetho tse remakileng tse nepahetseng le tse renderding tse rekiloeng ka ho fetesisa le boleng ba sehlahisoa.

Bokhoba ba mollo ba tungns Nakong ea ts'ebetso ea ho seha, likhohlano lipakeng tsa sesebelisoa le mosebetsi oa mosebetsi o hlahisa mocheso, o ka etsang hore kekene e tlohelle le ho nolofatsa lisebelisoa tsa lisebelisoa. Tsebo ea carbide ea carbide ea ho boloka thata le matla mochesong o phahameng o tiisa hore ho kuta lisebelisoa ho lula li sebetsa le tlasa maemo a hohelang.

Ho feta moo, botle ba lik'hemik'hale tsa hungsten ba ho hanyetsa ho hanyetsa moferefere le ho hlaseloa ke lik'hemik'hale tse fapaneng. Thepa ena e bohlokoa haholo ho lisebelisoa tse sebelisoang ka har'a lisebelisoa tse entsoeng ka lijalo tse sebelisoang ka matla.

Motsoako oa thepa ena o lumellaLisebelisoa tsa carbide cuttingHo fana ka melemo ea bohlokoa ka lisebelisoa tsa setso tse kang tšepe e lebelo le tšepe e thata. Li ka fihlela lebelo le phahameng la ho kuta, bophelo ba lisebelisoa tse telele tsa lisebelisoa, le boleng bo phethahetseng ba ho qetela. Sena le sona, se tlisa tlhahiso e eketsehileng, e fokotsehile ka nako ea phomolo, le litšenyehelo tse tlase tse tlase.

Qetellong, li-carbide carbide ke papali-christter ea papali sebakeng sa ho khaola lisebelisoa. Ho thata haholo, ho khathala ho hanyetsa, ho tsitsipana le ho senya le ho tsitsipana le lik'hemik'hale ho etsa hore ho be le lintho tse loketseng tšebetso e thata ho etsa litlhoko tsa lits'ebetso tsa sejoale-joale. Ha ho pelabo ea theknoloji e ntse e tsoela pele, ha ho pelaelo hore carbide e tla bapala karolo ea bohlokoa ea ho kuta theknoloji ea sesebelisoa.

Hamorao, re tla tsoela pele ho ntlafatsa tlhahisoleseling ka li-blades tsa indasteri, 'me u ka fumana leseli le lengata webosaeteng ea rona (Beliontool.com) blog.

Ho joalo, u ka ela hloko mesebetsi ea rona ea sechaba:

Poso: Hlakubele-17-2025